FRPP MODULAR series

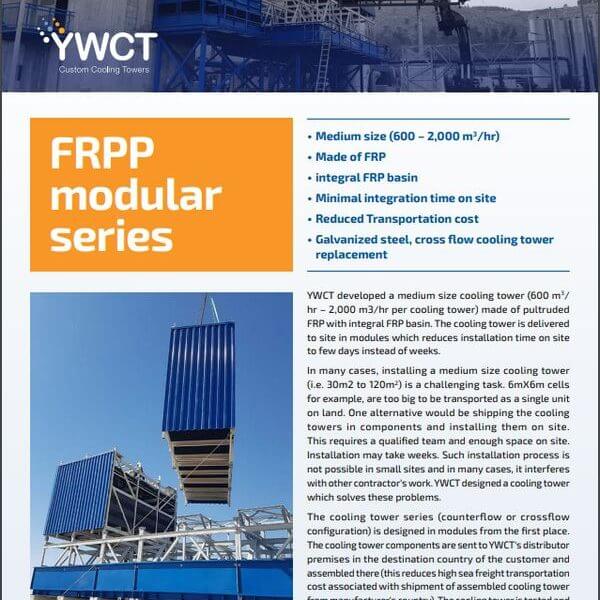

YWCT developed a medium size cooling tower (600 m³/hr – 2,000 m³/hr per cooling tower) made of pultruded FRP with integral FRP basin. The cooling tower is delivered to site in modules (sections) which reduces installation time on site to few days instead of weeks.

Cooling Tower designed in modules

The cooling tower is designed in modules from the first place. The cooling tower components are sent to YWCT’s partner premises in the destination country of the customer and assembled there (this reduces high sea freight transportation cost associated with shipment of assembled cooling tower from manufacturer’s country). The cooling tower is tested and then disassembles to modules which are shipped to the job site on trucks. Assembly on site takes two to five days and require a crew of five people and a small crane.

In many cases, installing a medium size cooling tower (i.e. 30m2 to 120m2) is a challenging task. 6mX6m cells for example, are too big to be transported as a single unit on land. One alternative would be shipping the cooling towers in components and installing them on site. This requires a qualified team and enough space on site. Installation may take weeks. Such installation process is not possible in small sites and in many cases, it interferes with other contractor’s work. YWCT designed a cooling tower which solves these problems.

Two additional advantages of this modular cooling tower:

- Materials. The cooling tower is made of pultruded FRP which is on the one hand strong, light and anti-corrosive and on the other hand, not expansive. FRP components are joined using SS HW.

- Integral basin. Unlike other solutions in the market YWCT’s modular cooling tower is equipped with integral FRP basin which could reach up to 2 m depth.

The bottom line is that the customer gets a high-quality cooling tower, with low shipment and assembly cost and quick installation time so the total cost of ownership is low.

Options

- Additional veil layers to increase corrosion resistance

- Pultruded FRP hand rails, walkways, and ladders

- Low-noise fans

- Complementary subsystems: filtration system, water treatment system, heat exchangers, VFD

- Nickel alloy connectors (e.g., Hastelloy C-22)

Features

- Pultruded fiberglass polyester factory made – assembled on site

- Heavy – duty cooling towers designed for industrial applications

- Optimal thermal performance design Highly resistant to corrosive environments